RD Chesters LTD in Bromyard has been supplying farms across Herefordshire and surrounding counties with feeds, seeds, fertilisers, and harvest products for over two decades.

Having produced feed blends in-house for their own use, for many years, they decided to expand their production. This was due to market demand. To scale up to meet market demand RD Chester decided to invest in an industrial mixer suitable for mixing feed. The mixer needed to comply with the feed industry regulations.

They also needed a mixer that was suitable to mix arctic lorry sized loads and also smaller batches like totes bags. The feed recipe that they had tried out on

their own farm offered excellent results. The replication of this secret recipe was key in their choice of industrial mixer. Local farmers that purchased the

product could see the proven results when seeing the health of the cattle on the farm, beside the mill.

Return on investment of an industrial mixer

Despite the outlay for the machine, the mill saw immediate benefits.

“Moving from a machine trailed behind a tractor to a static industrial mixer was a bold move. However, we saw the machine working elsewhere and liked its simplicity and mix consistency. The back-up service was also key. The fact that we knew that the machines last a lifetime was a consideration in the purchase,”

explained Mr. Thomas, managing director of RD Chesters Ltd.

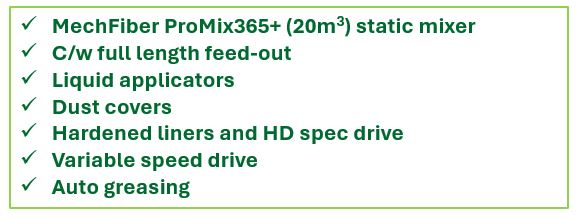

Design specifications

The engineers at KEENAN designed a bespoke mixer to suit the mill, which included a full-length feed-out for speed of emptying. They also added liquid applicators; dust covers and a hardened liner. The machine is run on a motor and has a low power requirement.

KEENAN ProMix machine specification