Biogas

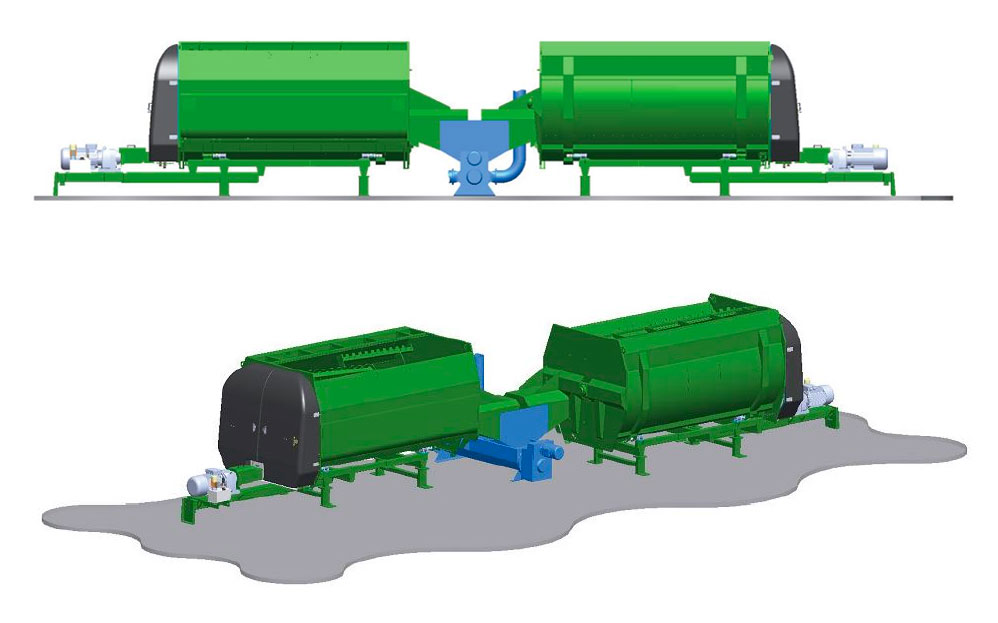

Customised Mixing Solutions for Biogas Plants

KEENAN mixers are proven to increase process efficiency and stability, while boosting power production and profit.

Unique mixing delivering results

KEENAN works with partners in the biogas industry worldwide. Our range of industrial mixers, with their unique mixing action, has been shown to produce a physical structure that leads to significant improvements in process efficiency.

Biogas plants working with KEENAN have shown increased process efficiency and stability, boosted power production and profit and are meeting the demand for tracking batch information.

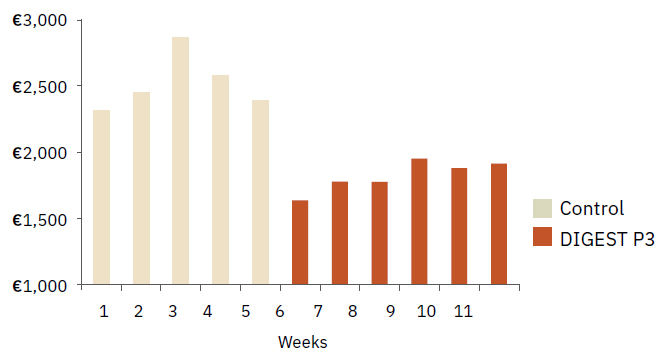

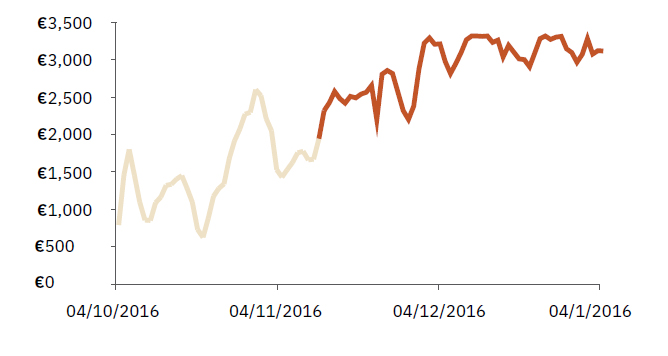

Trial work has independently confirmed the benefits of using a KEENAN for mixing on the overall process efficiency and profitability of biogas plants. The research results from one such study in Germany indicated a significant improvement in process stability during plant operation due to the homogenised substrate feed produced by the KEENAN machine.

The benefits were:

Beneficial to process efficiency

Increase in specific power production kW/m2

Decrease in standard deviation for power production & biogas production

Increase in average profit per day between £114 to £157

Cologne University of Applied Sciences on ABG Diez & Stinn, Germany in 2012.

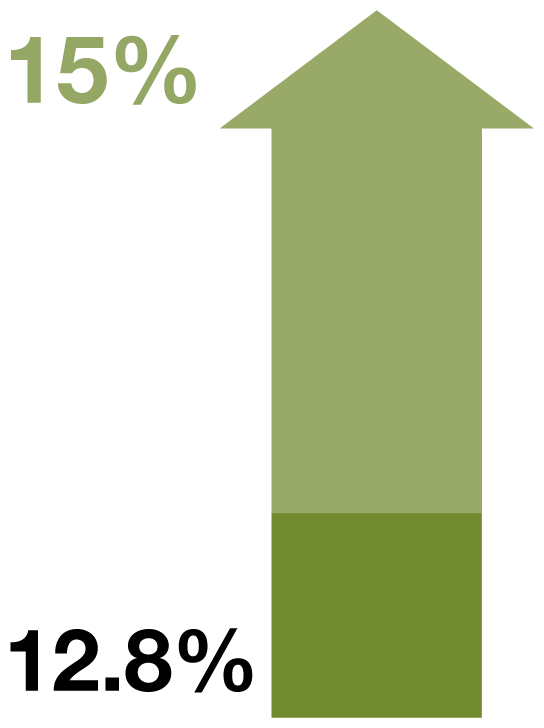

Digest P3

In addition to mixers, KEENAN Industrial, through our parent company, Alltech can offer Digest P3, an enzyme complex cultured through a process known as solid state fermentation. Digest P3 improves the profitability and anaerobic digestion by optimising biogas production.

DIGEST P3 releases the protein and energy from indigestible fractions of the feedstock, giving more fuel to the plant micro-flora and therefore producing more biogas.

Increase electricity production

€600 per day

Adding DIGEST P3 to your plant can increase electricity production by 12%, resulting in an extra €600 per day!

Decrease substrate feed costs

28% per day

Using DIGEST P3 in your biogas plant can reduce the substrate required to reach maximum output, resulting in up to 28% reduction in feed costs.